Calcit add capacity to meet rapid growth in the Ground Calcium Carbonate (GCC) market

Overview

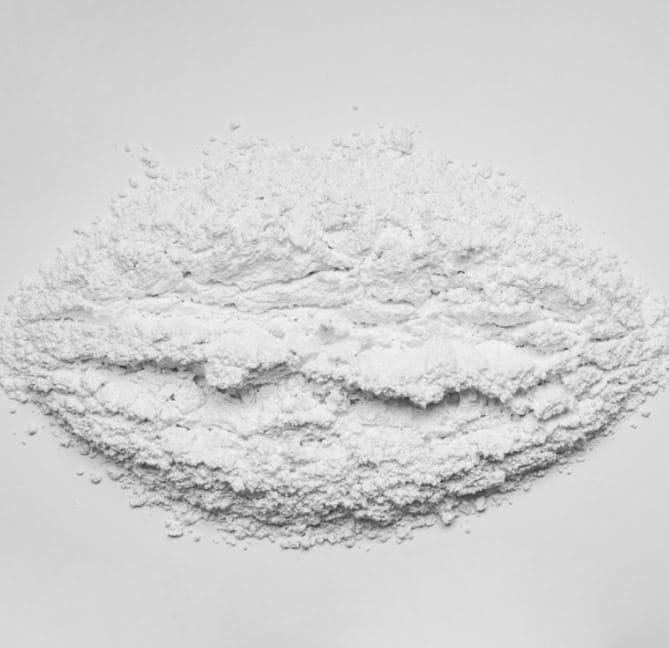

Calcit is one of the leading producers of calcium carbonate pigments, functional additives and granulates. They deliver a broad range of products to customers across Europe, serving key industries such as paper, paints, plastics, glassmaking, pharmacy, agriculture, ecology and construction.

The Calcit Group has three production plants located in Slovenia, Croatia, and the Netherlands. Calcit also has its own ore deposits in Slovenia and Croatia. Each site meets the highest criteria of quality, efficiency, and environmental protection.

Challenge

Calcit is focused on rapid expansion of their operations across Europe and need to increase production capabilities to meet customer demand.

They required large bespoke Cell Mills to produce Ground Calcium Carbonate (GCC) to increase processing capacity in Slovenia.

The equipment also needed to work in harmony with their existing Hosokawa Alpine vertical wet grinding mill.

Solution

Atritor worked with Calcit and Hosokawa Alpine to develop bespoke Cell Mills that simultaneously provide drying, deglomeration and coating. GCC production operates in a very competitive market, and this combined mechanical and thermal method of processing is the most cost effective.

High thermal efficiencies maximise the added value created from converting wet slurry into a dry powder used in many applications across the world.

In house design, casting and manufacturing capabilities coupled with 25 years’ experience in this sector of the minerals market, made Atritor the natural partner for Calcit, as they needed a quick, right first-time turnaround to meet production requirements.

Atritor have the end-to-end solution that allowed us to quickly satisfy more customers that want to increase the quality of their product and to enter the market for very fine products.”

Outcome

The additional Cell Mills will increase the amount of wet slurry that can be processed to produce the quality fine powder that customers require.

“Our increased penetration of the GCC market meant we needed to significantly increase our production capability to meet additional demand. The in-house design, production and manufacturing facilities at Atritor are an ideal fit for us, in what is a very competitive market. Atritor have the end-to-end solution that allowed us to quickly satisfy more customers that want to increase the quality of their product and to enter the market for very fine products.”

How can we help you?

We help process specialists and

innovators to find solutions for new applications, to valorise overlooked materials and upgrade

existing processes.